After a recent wash care accident with his sports jacket, Dr Albert Hackett (on secondment to us from the University of Michigan), has turned his academic attention away from screen mesh tensioning to investigate garment shrinkage.

Dr Hackett explained: “There are essentially two categories of shrinkage – felting and relaxation.

“Felting is unique to wool, because wool fibres have surface scales that cause differential friction effects. Wool fibres may swell, the scales expand and are lifted. This increases differential friction between fibres and interlocks and compacts them, which causes felting shrinkage.

“To reduce the risk of this, washing additives can lower inter fibre friction and reduce fibre swelling.”

Dr. Hackett continues: “As for relaxation shrinkage, during manufacturing textiles can stretch, and are sometimes shaped and dried under tension. Macroscopic stresses occur, but can be released by plasticization. The latter occurs when fibres swell in a liquid medium or when heat is applied during drying.

“Either action lowers the cohesive energy between amorphous polymer segments, and causes relaxation within the fibre matrix.”

Basically Doc, you need a new coat

Artwork Origination

Artwork Origination  Cap Manufacture

Cap Manufacture  Design Consultancy

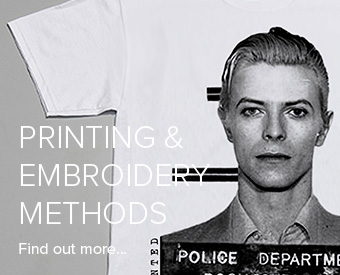

Design Consultancy  Embroidery

Embroidery  Fashion Photography

Fashion Photography  Garment Bagging

Garment Bagging  Digital Printing

Digital Printing  Garment Manufacture

Garment Manufacture  Garment Sourcing

Garment Sourcing  Relabelling and garment finishing

Relabelling and garment finishing  Screen Printing

Screen Printing  Watch us screen print

Watch us screen print