T shirt printing using screen printing techniques is the most common garment printing method.

Listed below are some of the best and most effective garment printing methods used by us to help you decide on what may be best for your garment designs.

Plastisol printing – the most common plastisol based print used in garment decoration. Good colour opacity onto dark garments, clear graphic detail, with as the name suggests, a more plasticized texture. This print can be made softer with special additives or heavier by adding extra layers of ink.

Water Based inks – these penetrate the fabric more than the plastisol inks and create a much softer feel. Ideal for printing darker inks onto lighter coloured garments. Also useful for larger area prints where texture is important.

Discharge inks – used to print lighter colours onto dark background fabrics, they work by removing the dye in the garment – this means they leave a much softer texture. They are less graphic in nature than plastisol inks, and exact colours are difficult to control, but especially good for distressed and vintage prints.

Foil printing – is what you would imagine. A glue is printed onto the fabric and then foils applied for a mirror finish. Due to the gold or silver foil used, minimum quantity of 100 applies.

Glitter/Shimmer – silver flakes are suspended in a plastisol ink to create this sparkle effect. Usually available in gold or silver but can be mixed to make most colours.

Metallic printing – similar to glitter, but smaller particles suspended in the ink.

Expanding ink (puff) – an additive to plastisol inks which raises the print off the garment, creating a 3D feel.

Caviar beads – again a glue is printed in the shape of the design, to which small plastic beads are then applied – works well with solid block areas creating an interesting tactile surface. Minimum quantity of 100 applies.

Four colour process – artwork is created using dots (CMYK) which combine to create the full spectrum of colours needed for photographic garment printing – this means an infinite number of colours can be printed using only 4 screens, making the set-up costs viable. The inks are required to blend and are more translucent, meaning a compromise with vibrancy of colour.

Gloss printing – a clear base laid over plastisol inks to create a shiny finish.

Mirrored Silver – Another solvent based ink but you can almost see your face in it.

Special screen printing effects

Fluorescents, Phosphorescents (glow in the dark),

Thermochromic garment printing (colour changes with heat)

Artwork Origination

Artwork Origination  Cap Manufacture

Cap Manufacture  Design Consultancy

Design Consultancy  Digital Printing

Digital Printing  Embroidery

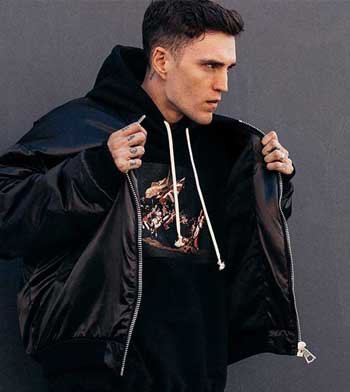

Embroidery  Fashion Photography

Fashion Photography  Garment Bagging

Garment Bagging  Garment Manufacture

Garment Manufacture  Garment Sourcing

Garment Sourcing  Relabelling and garment finishing

Relabelling and garment finishing  Screen Printing

Screen Printing  Watch us screen print

Watch us screen print